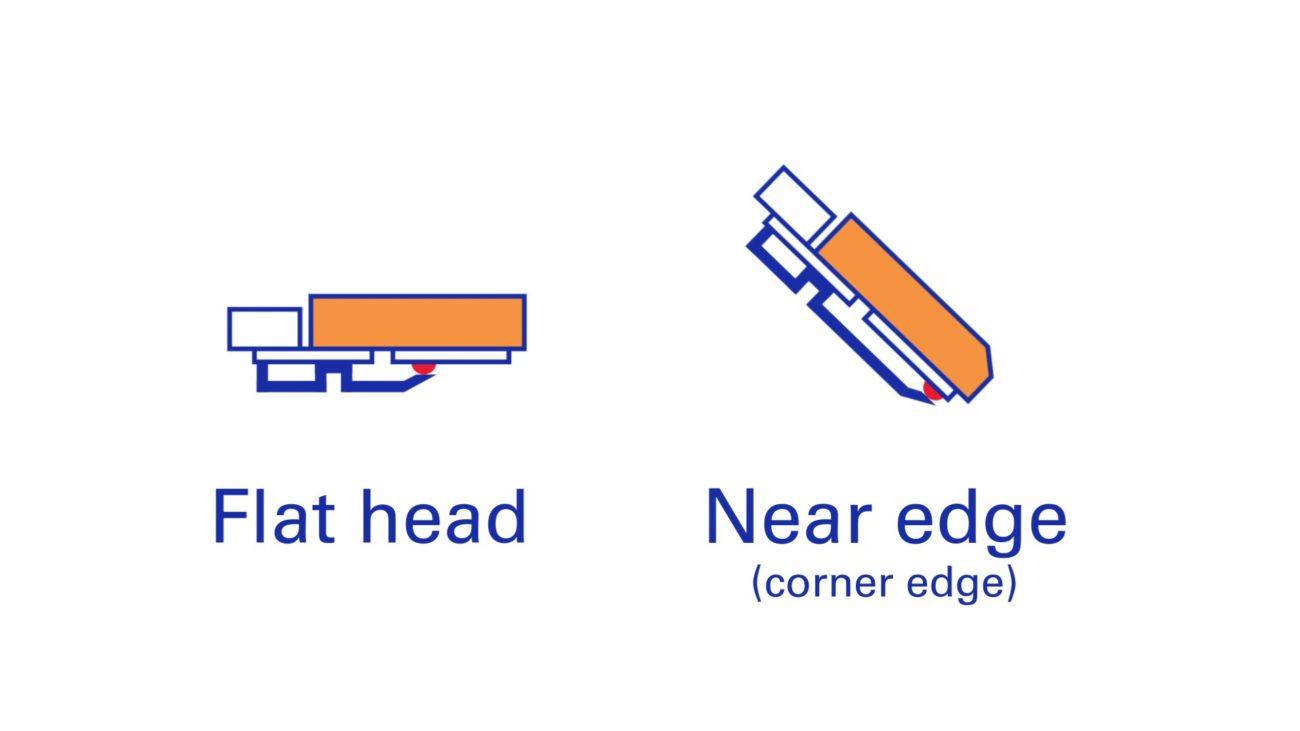

Thermal Transfer Printing is a method where heat is used to transfer ink from a ribbon onto the substrate. For example, for the printing of barcodes. The heat comes from a sophisticated print-head that shapes the impression. Two different types of Thermal Transfer Printers are used: Flat-head and Near-edge, also known as Corner-edge.

Flat-head printers

Flat-head printers have a traditional, horizontally positioned print-head. The ribbon stays in contact with the label for some distance while passing the print-head, before parting after the peel-point. This ensures better encouragement of the image on the substrate. These models will generally print at speeds between 2-10 IPS.

Near-edge printers

Near-edge printers with their floating print-heads are positioned at an angle, so they can run more than twice as fast. Speeds of over 10 IPS are the norm. However, even up to 34 IPS can be reached by certain ribbon-printer combinations. Ribbons for Near-edge printers stay in contact with the labels only for an instant prior to the peel-point. The floating print-head of a Near-edge printer means not having to make adjustments for various media thicknesses e.g. printing on food packages.

What’s the difference?

Each of the printer types requires its own ribbons. A Near-edge Thermal Transfer Ribbons is designed to release the ink much quicker, which is required for faster print speeds. The ribbons are also often made with a thinner PET film, creating more ribbon capacity and reducing change-over time. Another advantage is that it produces less plastic waste.

DNP offers a wide portfolio of both Flat-head and Near-edge ribbons. You can find these on the product pages of our website. On this page you can find more info on the specific questions you might have on TTR printers.

If you need help or advice in choosing the right ribbon for your Flat-head or Near-edge ribbon, we are here to help!