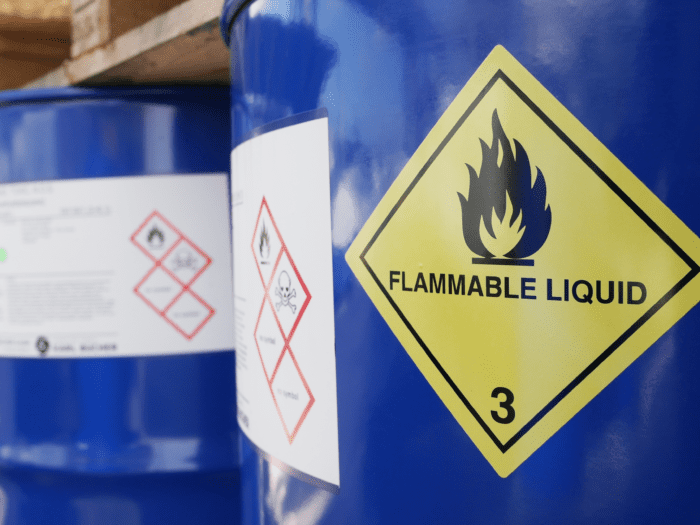

What Thermal Transfer Ribbon should we choose for chemical and heavy industry applications? Oil barrels, heavy industry items, hazardous chemicals labelling and markings. Where shall we start?

Safety is a key priority when supplying chemicals within the EMEA market. Which is why, to ensure both human and environmental safety, the packaging of items are carefully marked with safety and warning symbols as well as, instructions should one get in direct contact with the substance. Safety plays a crucial role during the manufacturing, transport and retail stages. Certainly, the ability to reduce workplace incidents and to respond swiftly to quality audits and product defects can make or break the success of any business.

In view of this, today’s businesses are to comply with specific classification, labelling and packaging regulations such as the UN’s Globally Harmonised System of Classification and Labelling of Chemicals (GHS). As a consequence, such optimised traceability and communication measures allow professionals within the chemical industry to facilitate a safe manufacturing and trading process. Hence, the quality of the variable code printing such as warning signs and barcodes is therefore of crucial importance.

Find the Thermal Transfer Ribbon that fits your specific needs.

When it comes to securing variable information on substances such as cleaning agents, pesticides or paint, the most important step is to choose a fitting printing technique. In any case, chemical and other exposure put any print to the test regardless of the printing technology. Even so, even in the toughest environments, Thermal Transfer printing proves to be suitable to render industry compliant results with resistance against:

Selecting the right Thermal Transfer Ribbon is a crucial part of ensuring traceability throughout product lifetime and long after. Yet, before making a decision on the ribbon type, it’s essential to know the most important factors of what makes a perfect thermal transfer print. When choosing which Thermal Transfer Ribbon to go with, first consider the following:

This way, by harmonising ribbon, substrate, printer type and printer settings and application, we can assure of producing the ultimate print result.

DNP Thermal Transfer Ribbons are produced using strict quality measurement systems to ensure high-quality products to all our customers. Owing to stringent regulations, within the chemical industry, most DNP Thermal Transfer Ribbons are developed to comply with one or more industry certifications. Should you wish to find out which ribbons are compliant with your specific application, just take a look at our compliance overview. The DNP assortment contains wax, wax resin and resin ribbons to match different needs. The ultimate chemical resistance can be found in our R550 resin

With production running on the side, testing new products can be challenging at times. This is why we offer to help you test products in DNP’s in-house lab or on-site. Let it be a challenging application that you need our help with, or finding the right ribbon and substrate combination, DNP’s knowledgeable product and industry experts are ready to take your requests at any time.

Get in touch with us to receive personalised advice from our TTR experts.