Depending on the type, a Thermal Transfer Printer requires a specific ribbon. The type of ribbon depends on the printhead. It is also important to know whether a printer is designed to work with ribbons with ink on the outside or ink on the inside. This page answers typical questions on the relationship between ribbon and ink.

Flat-head printers have a traditional printhead that can generally provide image resolutions between 200 and 600 dots per inch (DPI), in some cases, this can go up to 1200 DPI. Their ribbons are married with labels for a small distance to the peel point after passing the heating element. These models will generally print at speeds up to 12 inches per second (IPS). Some printers are able to print up to 20 IPS when the right ribbon is selected.

In contrast, near-edge printers with their floating printheads will run more than twice as fast. Speeds over 26 IPS are the norm where 55 IPS is also reached by certain printer-ribbon combinations. Ribbons for near-edge printers are married with labels only for an instant prior to the peel point, requiring a special formulation engineered for quick release of ink from the base PET film. A floating printhead means not having to make adjustments for various media thicknesses. In addition, the image resolution for these printers is lower at between 200 to 300 DPI.

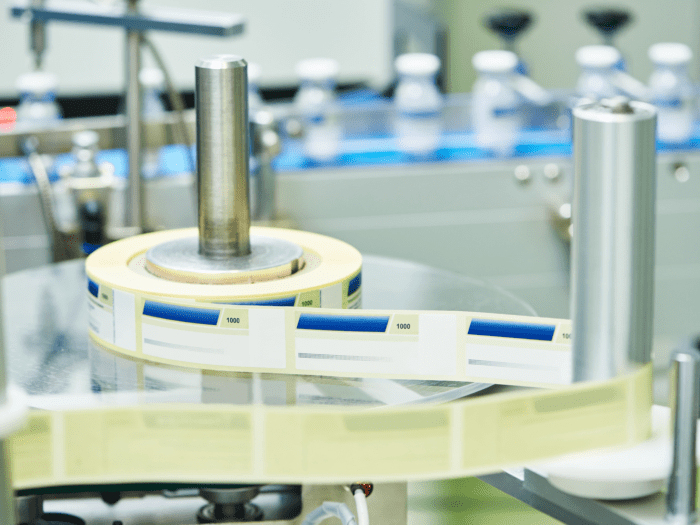

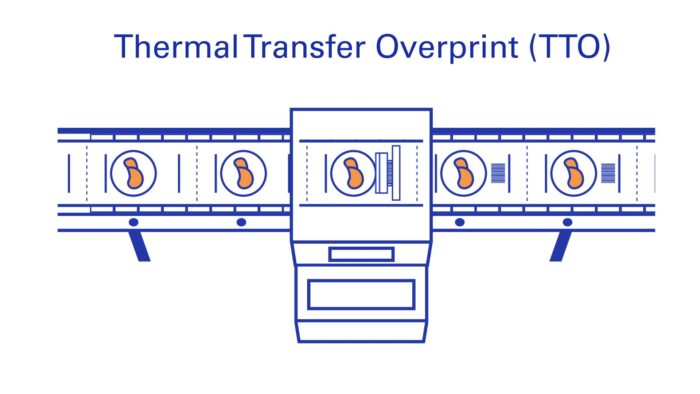

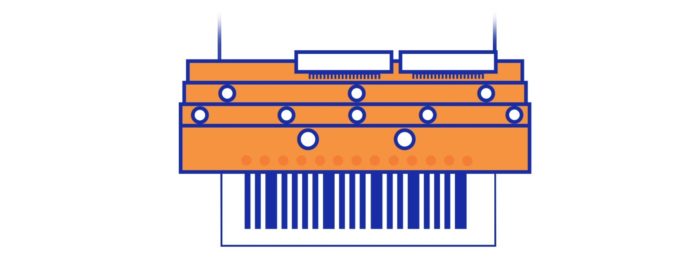

Thermal Transfer Overprint (TTO) is a method where heat is used to transfer ink from a Thermal Transfer Ribbon onto a flexible substrate like food, beverage, and medication packaging. This technique is designed for use on flexible packaging and is used for the printing of barcodes and variable information such as best-by dates and serial numbers. The challenge of printing on flexible packaging on a high-speed production line is to guarantee high-quality printing with compliant variable data on each and every item. In-line printing is done at high speeds of 20 IPS and therefore requires specific Thermal Transfer Ribbons. This animation explains more about TTO printing and the selection of the right ribbon.

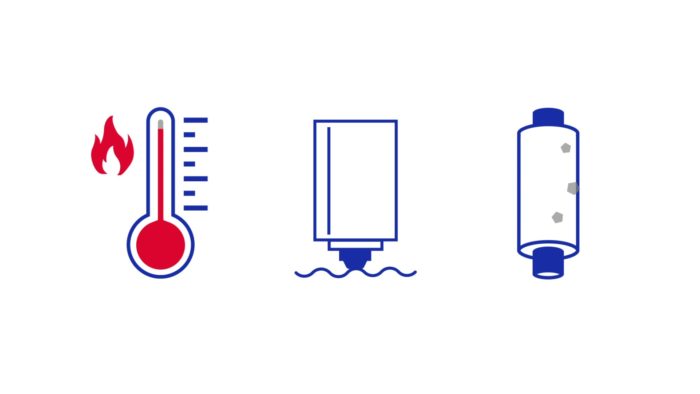

It is important to realize that the correct use of a quality ribbon will extend the life of the most valuable component of your printer: the printhead. Ribbons can play a role in the wear and tear on printheads. In essence, there are three causes for this: too much heat, printhead in direct contact with a rough substrate and pollution. When a printhead is not performing correctly, white lines and dots will come out on the print. The quality of the print will deteriorate and the scannability of barcodes becomes problematic. To protect your Thermal Transfer Printhead, make sure to:

Depending on the type of printhead, a Thermal Transfer Printer uses different ribbons. A ribbon needs to be specific for a flat-head and a near-edge printer. Within the near-edge category, the TTO printers also require their own specific ribbons. This mostly has to do with the speed of printing, which requires a specific build-up of the release layer of the ribbon. This layer determines how fast the ink releases from the ribbon when heated. With the DNP ribbon finder you can browse to our assortment. Additionally, printers differ on whether they require the ink to be on the outside or on the inside of the ribbon. All DNP ribbons can be supplied with the inkside “IN” or inkside “OUT”. You can indicate this on ordering or when requesting a sample.

Thermal Transfer or Direct Thermal are two common systems in the printing of variable information. Often, printers are able to print with both systems, as they use the same thermal printhead. Direct Thermal uses a special heat-sensitive paper that colours under the influence of the printhead. Thermal Transfer Printers transfer ink from a ribbon onto the substrate. Direct Thermal is mostly used for variable information with a short lifespan, such as receipts. Thermal Transfer is used when information should be readable for a longer period of time. In this post, we explain more on the differences and advantages of both systems.

Feel free to contact us anytime for any questions you may have.