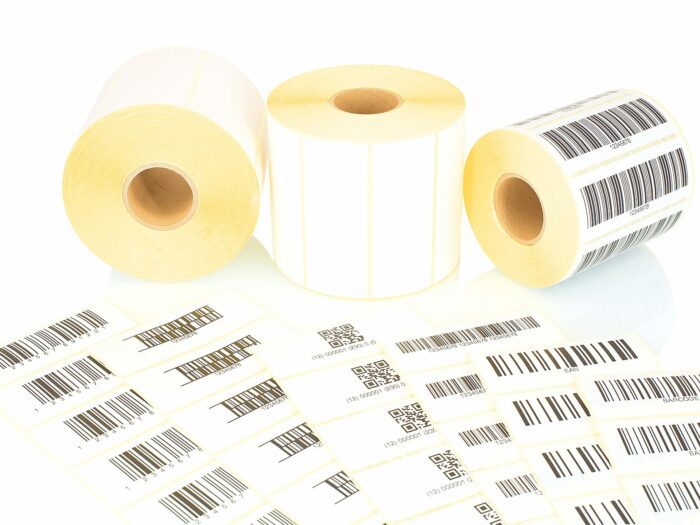

Thermal Transfer is used for making lasting impressions on different label materials. A specific substrate requires a suitable Thermal Transfer Ribbon. The type of exposure (e.g. chemicals, abrasion, light) also determines whether a wax, wax resin or resin label should be selected. On this page, we explain more on how to pick the right ribbon for your label.

The first step is to find a label material that suits your application in terms of appearance, durability and expected exposure. Based on this, a Thermal Transfer Ribbon can be selected that prints well on the label material and meets the same requirements in terms of durability and exposure. Some label substrates work better with wax, while others need a wax resin or resin to achieve the optimal results.

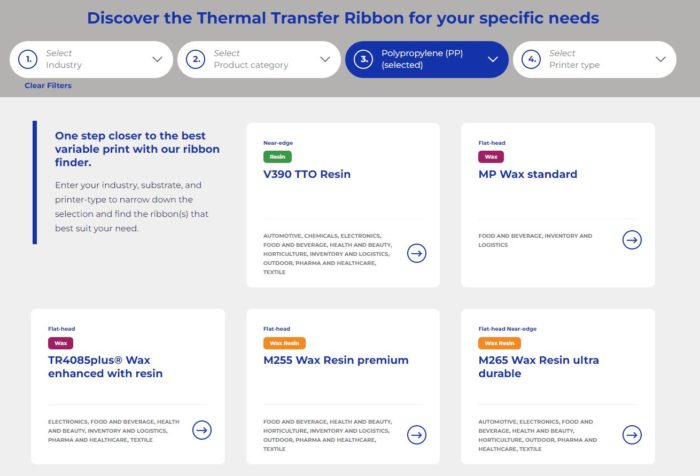

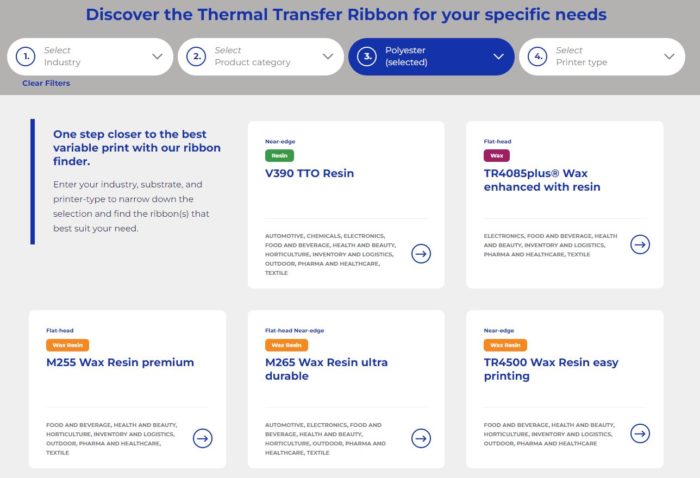

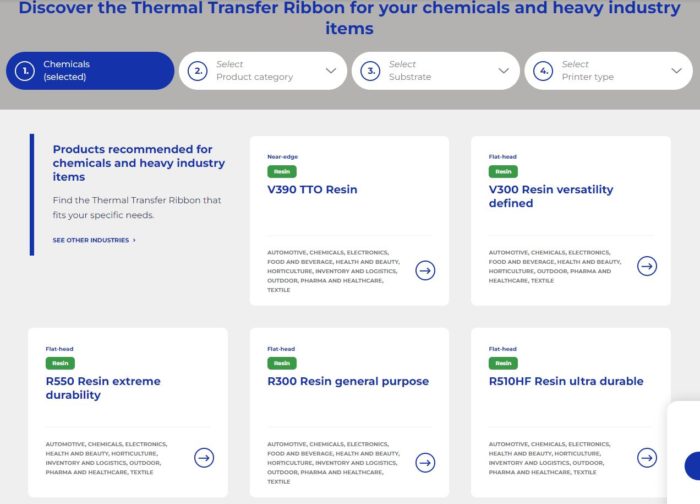

DNP Thermal Transfer Ribbons are tested on different materials. To make the first step in selecting the right ribbon for your label, you can use our ribbon finder. Enter the label substrate and the printer type and find matching ribbons. You can further refine your search by adding the industry and ribbon type. Feel free to contact us when you need more specific advice

Some materials, such as uncoated paper and Tyvek® have an uneven surface. Wax ribbons are the most natural choice for these materials as the wax will melt into the cavities, overcoming the unevenness and securing a dark print result. In many cases, more resistance and durability is needed, making it necessary to use a wax resin or even a resin ribbon.

DNP has developed several wax resin ribbons, such as TR4500 and M255, that do an excellent job on these materials. For the toughest jobs, we even offer a resin that works on uncoated paper: V300. Use our ribbon finder to determine which Thermal Transfer Ribbons work well on your label.

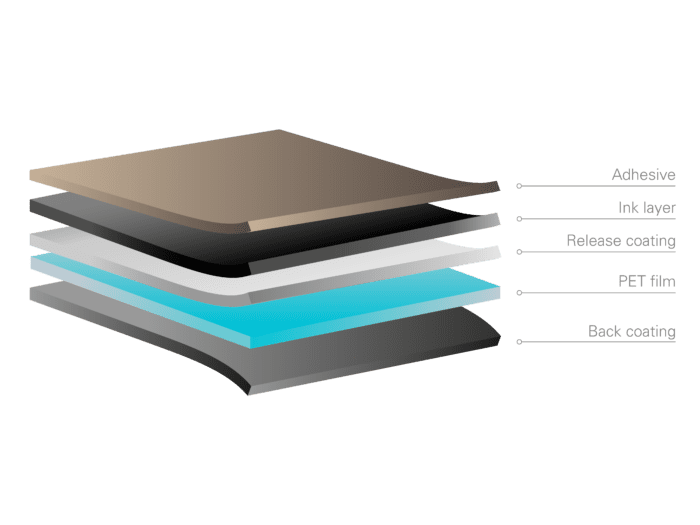

Very smooth materials require specific ribbons in order to be properly printed. It can be a challenge to apply a Thermal Transfer print on a glossy label with a varnish or made from vinyl. In these cases it is important that a ribbon contains a special adhesive so the print can be “glued” to the substrate. Such adhesive layers are commonly found in resin ribbons, such as V300 and R300.

On the wax resin end, DNP has developed M265, which also works well on varnished labels. You can use our ribbon finder to determine which ribbons work best with your label material.

To determine which Thermal Transfer Ribbon should be used on a specific paper label, several factors should be considered. Important to know is if a label is made with coated or uncoated paper and whether a varnish is applied on the surface. Generally speaking, uncoated papers work best with wax, as these ribbons are best suited to overcome the unevenness of the paper, securing a sharp, dark print. Smoother papers, like coated or glossy paper can be easily printed with most type of ribbons, while paper with a varnish limits the choice to specific wax/resin and resin ribbons. Specific requirements, like rub resistance, might require a different choice of ribbon on, for example, uncoated paper. With V300, DNP has developed a ribbon that also works on labels made from uncoated paper. DNP had developed a thermal transfer ribbon selector to help you in finding a suitable ribbon for your paper label. Our technical experts are available to help you with specific questions.

For the most common materials for synthetic labels, such as PE, PP and PET, a wide range of Thermal Transfer Ribbons will do the job. Depending on the required durability, wax, wax/resin and resin ribbons can be used. For certain label substrates, for example vinyl and polycarbonate, the choice of ribbons is more narrow. For these specific examples, certain resins are the best option. The V300 ribbon that was developed by DNP will print on both of these materials as well as a wide range of other synthetic labels. The Thermal Transfer Ribbon finder will help you in selecting the right ribbon for your label. Our technical experts are available to help you with specific questions.

When you’re thermal transfer printing on plastic, it is important to know what is the exact material. The category plastic contains a lot of different materials, such as PE, PP, PET and PVC with specific characteristics. Some of these materials can be printed with any ribbon, while others require a very specific resin or wax resin. If you know the specific type of plastic material you want to use for Thermal Transfer Printing, you can use the ribbon finder to determine what ribbons are available. Our technical experts are available to help you if you need further assistance or more specific advice regarding thermal transfer plastic labels.

Thermal Transfer Print on cardboard is mostly done on labels that are then applied to the cardboard material. It is also possible to apply the Thermal Transfer Print directly onto the cardboard. In this case it is important to know what material is used for the outer liner of the cardboard or the corrugated box. Very often this is uncoated paper, which is easily printed with a wax ribbon. When a more durable print is required, the liner of the cardboard can also be printed with specific wax resin or resin ribbons. You can use the ribbon finder to determine which Thermal Transfer Ribbons can be used on your cardboard or corrugated box liner. Our technical experts are available to help you if you need further assistance or more specific advice.

Labels made of Polypropylene or PP are commonly used in a wide range of applications. PP labels are appreciated for their resistance against a wide range of chemicals. The labels are used both indoor and outdoor and have a broad temperature tolerance. Polypropylene labels are easily printed with Thermal Transfer and a high quality result can be achieved with many different ribbons. As a starting point for flat head printers, DNP recommends TR4085+ as Wax ribbon, M255 as Wax Resin and V300 as Resin. For near edge printers, DNP recommends M295HD 4.0 as Wax Resin and V390 as Resin as the first option. Depending on specific requirements (e.g. colour) and exposures, another TTR might be necessary.

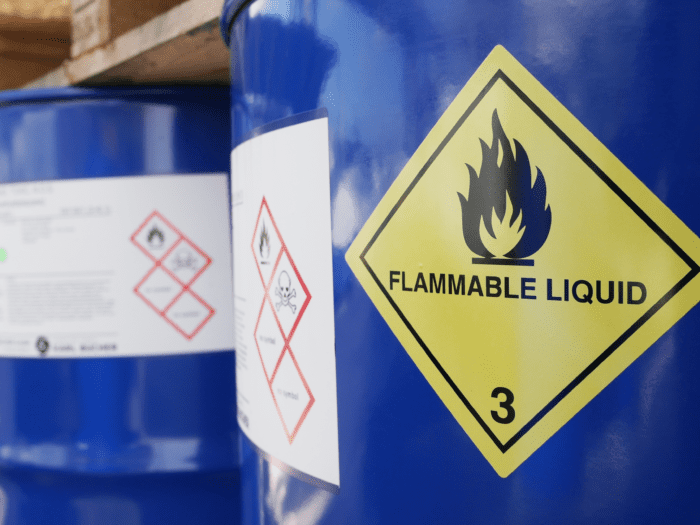

Polyester is used for highly durable labels that last many years. It is often used for chemical labeling or in technical environments where the readability of the label should last the lifetime of a component. Although many Thermal Transfer Ribbons will print on a polyester label, the required durability of the combination of label and ribbon makes a resin the typical choice. The DNP assortment contains a wide selection of resins that deliver a durable Thermal Transfer print on polyesther labels. This ranges from the versatile V300 to R550, our most rugged ribbon. Depending on specific requirements (e.g. colour) and exposures, another TTR might be necessary.

For labels on chemical containers it is especially important that information remains readable. This means that the print should not only be able to withstand the chemical inside the container, but also exposures like sunlight, abrasion and time. For the Thermal Transfer printing of chemical labels, DNP recommends a resin. Resins will provide the most durable print and our assortment offers a wide selection of ribbons for specific situations and in different colours. This ranges from the versatile V300 to R550, our most rugged ribbon. Depending on specific requirements (e.g. colour) and exposures, another TTR might be necessary.

Horticultural environments can be one of the most demanding environments for printed information. Exposure to intense sunlight, variable temperatures, high humidity and chemicals/fertilizers can easily make a print unreadable. Thermal Transfer print, in combination with the right label substrate, make it possible to create prints of the right durability on, for example, plant passports. The durability requirements for a print in a horticultural environment vary greatly: from logistical information that only needs to last a few days to plant registration details that should remain readable and scannable for years. Therefore, we offer a wide range of labels that are suitable for use in different horticultural applications.

The automotive industry uses a lot of printed information, both inside and outside the vehicle. Within the vehicle, the printed information and barcodes are mostly required to last the full lifetime of the car, truck, or motorcycle. Requirements differ per area or part where the print is applied: high temperatures, direct sunlight, and exposure to car liquids or abrasion determine what is needed from the printed label. Thermal Transfer is especially suitable to make durable prints on labels within a car. DNP offers a wide range of Thermal Transfer Ribbons for use on automotive labels such as the versatile resin V300 and the highly durable and temperature resistant R550.

Logistic labels are used to identify products so that they can be tracked and traced throughout the supply chain. Often, the information on such a label is only needed for a few hours or days, for example during movements in a warehouse or the door-to-door delivery of a parcel. In other cases, the information is required to remain readable and scannable for much longer, examples of this are ocean shipping and long-term storage. Thermal Transfer Print is very suitable for printing of information on logistic labels that are required to last a bit longer or are exposed to thinks like abrasion and sunlight during the movement of the goods. In many cases, a wax ribbon, like TR4085+, will deliver an excellent result. On the other end of the spectrum, extremely durable resins like R510 and R 550 will provide a print that scans even after the most extreme exposures.

To make a good thermal transfer print on electronics, for example, circuit boards, several key factors must be considered: Substrate, ribbon, printhead temperature, pressure, alignment, cleaning, and proper handling. Choosing the right substrate such as polyimide or polyester films, using heat-resistant and durable ink based on resin, setting printhead temperature and pressure correctly, proper alignment, cleaning circuit board and printhead before printing and handling the circuit board with care. Additionally, it’s important to test and verify the print quality before mass production. DNP is offering a range of ribbons that are suitable for the printing of circuit boards. R510 is a resin that is available in a range of different colors and provides a highly durable print.