Thermal Transfer Overprinting with V390 resin delivers durable crisp dark images on a wide range of flexible materials and near-edge label printers. Durable high quality are printed at high speeds. The product is delivered on a 4.0-micron film, allowing roll lengths of up to 2000 meters. This enables longer run times and less plastic waste. This latest DNP innovation delivers on its promise: Versatility

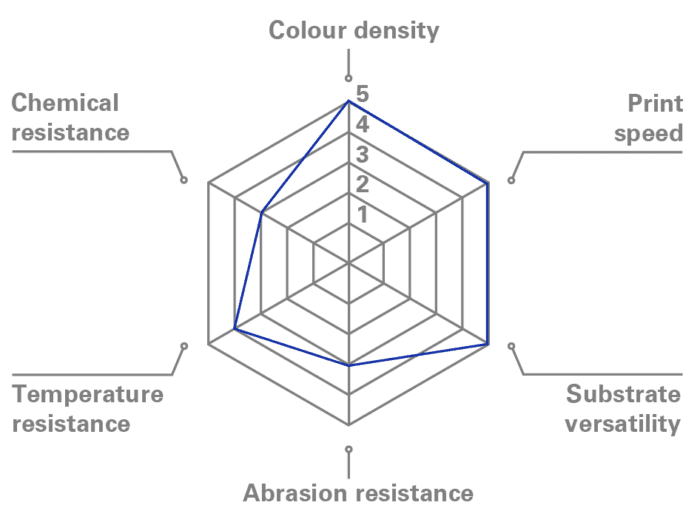

Producing high-quality TTO print on different materials and in varying production circumstances generally requires a range of ribbons and time to make the combination of ribbon, printer and material work optimally. To overcome this, DNP first developed V300 – Versatility Defined resin for flat-head printer, enabling high-quality print on materials ranging from paper and polypropylene to PET. To bring this kind of versatility also to the TTO and near-edge market, we are now bringing V390 TTO resin. It performs a wide variety of flexible materials and label substrates for near-edge printers. The crisp, dark images are printed at high speeds of up to 28 IPS. V390 provides superb durability against common chemicals and solvents and allows for longer run times and less plastic waste due to the ultra-thin PET film.

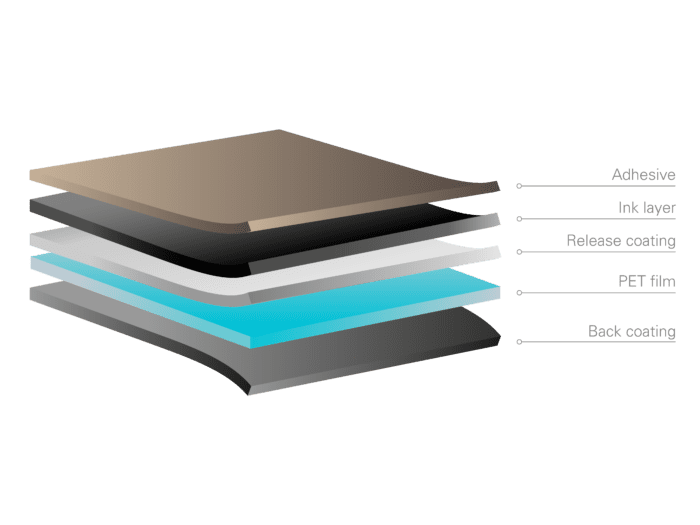

Ink: Resin

Colour: Black

Total thickness: 5.4 ± 0.9µm

Base film thickness: 4.0 ± 0.4µm

Ink thickness: 1.4 ± 0.5µm

Store between 5 – 35°C, 20-80% relative humidity, keep away from heat and direct sunlight.

| Aluminium |

| Paper coated |

| Paper flood-coated |

| Paper gloss |

| Paper synthetic |

| Paper uncoated |

| Paper vellum |

| Polyart |

| Polyester |

| Polyethylene (HDPE) |

| Polyethylene (LDPE) |

| Polyimide |

| Polypropylene (PP) |

| Polystyrene |

| Teslin® |

| Textile nylon |

| Textile taffeta |

| Top coated vinyl |

| Tyvek® brilion |

| Varnish (other) |

| Varnish (UV) |

| Vinyl |

Follow the link to download your technical data sheet

DNP specialises in helping you harmonise substrate, printer and ribbon. All this, with ribbons tailored to your needs and technical support in our DNP lab or on-site, in your own production environment.

Because at DNP, we believe in partnership, that provides the swift and tailor-made answers that you need.