What is a wax ribbon?

Thermal Transfer Ribbons come in three main groups: wax, wax/resin, and resin. This animation and article explain the specifics of wax Thermal Transfer Ribbons. Wax ribbons are named after the wax ingredient that carries the ink. A good product ensures a dark, high-density print that enables flawless scanning.

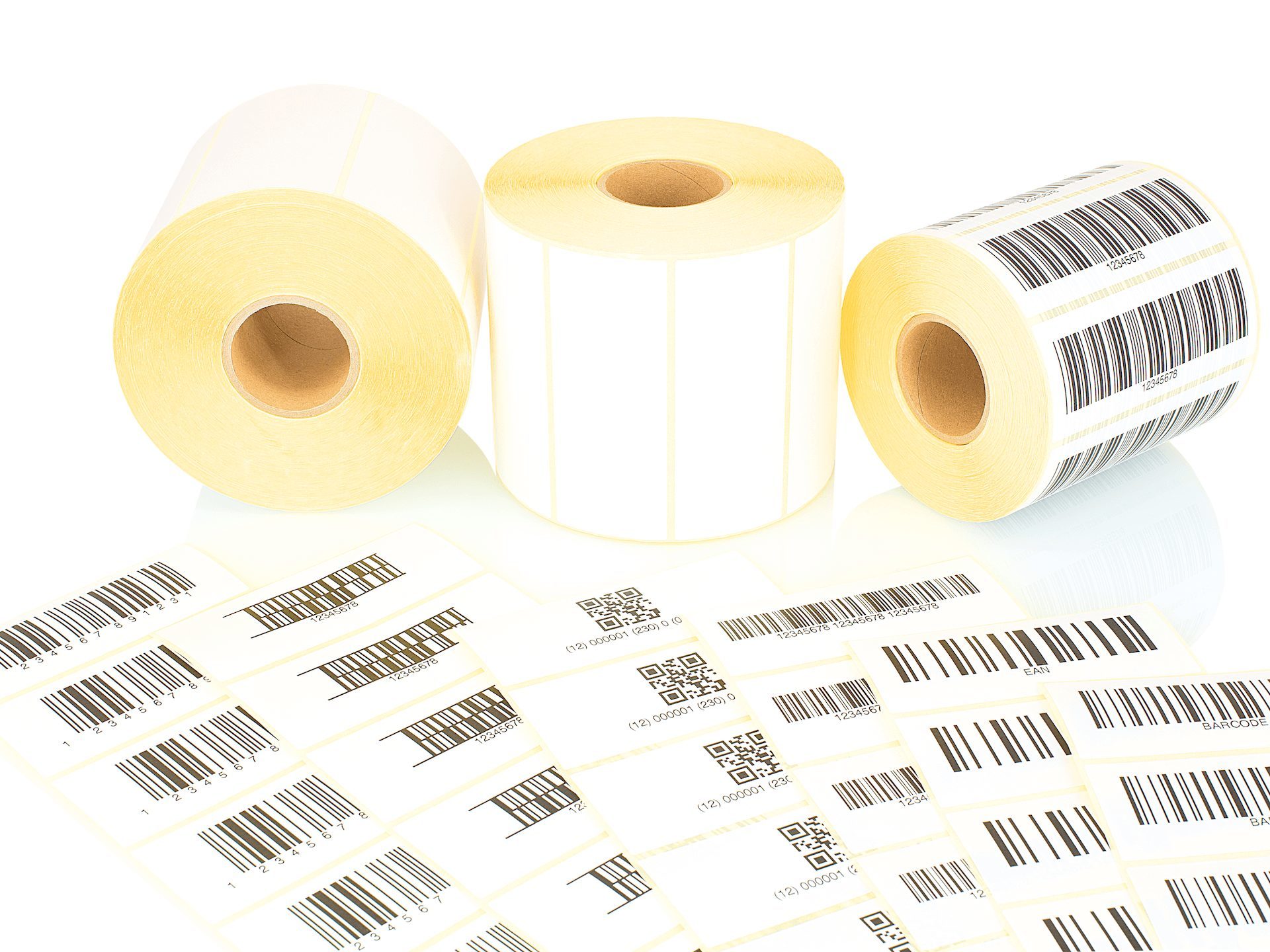

What are wax ribbons used for?

Typical applications of wax ribbons include labels for shipping and inventory management, as well as retail tags. However, you may come across wax-printed labels and other substrates in many industries. This comes as wax formulations are the most common ribbons used in Thermal Transfer Printing.

What is the difference between wax and resin ribbons?

Compared to resin and wax/resin ribbons, wax ribbons are easier to print. The ink is transferred at lower heat settings on the printer and therefore the printing process requires less energy. Another difference between wax and resin ribbons is that the prints made with wax are less resistant to friction/abrasion and exposure to things like heat, solvents, and other chemicals. The next difference between wax and resin ribbons is the ability to print on rough surfaces, such as uncoated paper. In this case, wax ribbons are a better choice as they can overcome he unevenness of the surface by melting into it, ensuring a dark and crisp print result.

How to print with wax ribbons?

Printing with a wax ribbon is normally done at the lower ending of the heat-setting of the Thermal Transfer Printer. The easy transfer of the ink onto the substrate ensures a hassle-free printing process.

On paper materials, one can often achieve a print speed of 4-10 IPS, whereas on smoother materials you may reach up to 8-20 IPS depending on the settings, print material, and formulation.

What substrate should print on with a wax ribbon?

Of all the Thermal Transfer Ribbons, wax formulations give the best print results on rougher substrates such as uncoated paper and Tyvek®.

The wax easily melts into the uneven areas ensuring dark, high-quality print results. In addition, wax ribbons also print well on other papers and a range of synthetic materials such as PE and PP.

What kind of wax formulations does DNP offer?

DNP provides a complete range of wax ribbons that enable you to easily print high-quality coding on a wide range of materials depending on your exact needs.

The DNP range includes resin-enhanced formulations for additional durability and sharp-edge definition such as the renowned TR4085Plus®, the industry’s leading wax product since its introduction to the market in 2000, or MP Wax, DNP economy wax for standard applications.

The overall portfolio also includes a variety of colored wax ribbons such as TR3021 (Red), TR3022 (Blue), or TR3023 (Green) for specialty applications.

Are you in need of technical support in finding the right Wax Thermal Transfer Ribbon formulation? Our experts are specialised in securing the best possible print result for you. We are here to help!

In what industries are wax ribbons used?

Wax ribbons are seen in all industries where they are mostly used for production of high quality logistical prints. Compared to other printing methods, such as direct thermal, thermal transfer print with wax delivers a more durable and easy-to-scan image. The applications vary from box labels, crate tags, shelf labels and shipping labels. On our industries pages, you can find which wax ribbons are recommended for the different applications.