Curious about the possibilities of Resin ribbons? Readable and scannable codes can be a life-saver in environments that demand high durability from both label and print. As an example, packaging of chemicals/pharmaceuticals, medical devices, electronic/laboratory markings, car parts and pipe identification are items where proper product identification ensures that critical information is readable several years after printing. A Resin is the best choice to create lasting prints.

Thermal Transfer has proven to be a popular, highly durable print technique which produces scannable print results. Therefore, Thermal Transfer Printing with a resin is the preferred choice when for applications requiring durability against:

Find the Resin for your application requirements.

In a Resin product, the ink is captured in resin. Resins are hard and provide the highest possible resistance against severe abrasion, harsh chemicals or other severe circumstances. Resin ribbons require a higher transfer temperature setting of the printer over wax or wax resin ribbons. Typical applications where resins are used are labelling of chemicals, marking of laboratory samples and challenging circumstances in, for example. the automotive and electronic industry.

When it comes to resins, significant differences are usually present when compared to wax and wax resin ribbons:

All DNP ribbons are formulated to consistently deliver high-quality variable print. From standard coding to highly specific applications and substrates, we supply a ribbon that fits your needs.

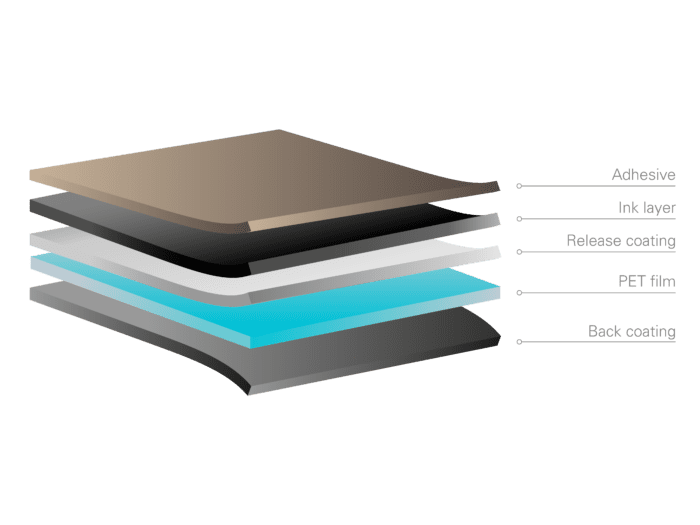

Resin TTR ribbons have an extra layer that is added to enhance the durability of the print. This binder layer is the first layer that contacts the substrate when the image is transferred. It serves as an adhesive to secure the layer with ink on the material. The binder is activated by the heat of the printhead, this is also one of the reasons that resin ribbons require higher temperature settings. An additional advantage of the binder is that it helps overcome the challenges of printing on very smooth label materials.

Different substrates and durability requirements might require a specific formulation. That is why the combination of ribbon, substrate and correct printer settings should be considered to determine the quality of the print. For instance, Resin Thermal Transfer Ribbons generally require a higher transfer temperature setting of the printer over wax or wax/resin ribbons. However, resin ribbons also offer more durability of the printed image. In general, resins give the best print result on synthetic material such as PE, PP and PET. Printing on uneven materials, such as uncoated paper, is often more challenging. However, with V300, DNP has developed a resin that even performs well on uncoated paper and other rough materials.

Resin ribbons are used for resistance against exposure or abrasion, long life or when the impact of failed prints is high.

Since the early ’80s, DNP (Dai Nippon Printing Co. Ltd.) has built-up a long-standing history of developing Thermal Transfer Ribbons. Its resin assortment is constantly evolving to meet evolving industry requirements. Our R&D team and market experts work closely together to bring relevant innovations to the market. As a result, our latest introductions offer versatility on many different substrates for a wide range of applications. V300 is designed for flat-head printers while V390 offers similar characteristics on TTO and near-edge printers. This reduces the number of different ribbons needed to deliver the correct variable print.

DNP specialises in helping you harmonise substrate, printer and ribbon. All this, with ribbons tailored to your needs and technical support in our DNP lab or on-site, in your own production environment.

Because at DNP, we believe in partnership, that provides the swift and tailor-made answers that you need.