Colour thermal transfer printing offers a versatile and efficient solution for various printing applications. From enhancing visual appeal to ensuring safety and compliance, the use of thermal transfer technology has become increasingly popular. In this article, we will explore the benefits of using colour thermal transfer printers and typical applications. As well as, the different types of TTR available, and how to match label and ribbon for optimal results.

Enhancing your printing experience: Why use a thermal transfer printer?

Thermal transfer printing is an excellent choice when it comes to printing variable data. Thanks to the perks of this printing technology, thermal transfer printing provides results of the highest quality and durability. Looking for prints that remain well visible for six months or longer? Prints that may be exposed to harsh conditions such as abrasion, chemicals, light, extreme temperatures? Then thermal transfer printing is the technique to choose for your situation.

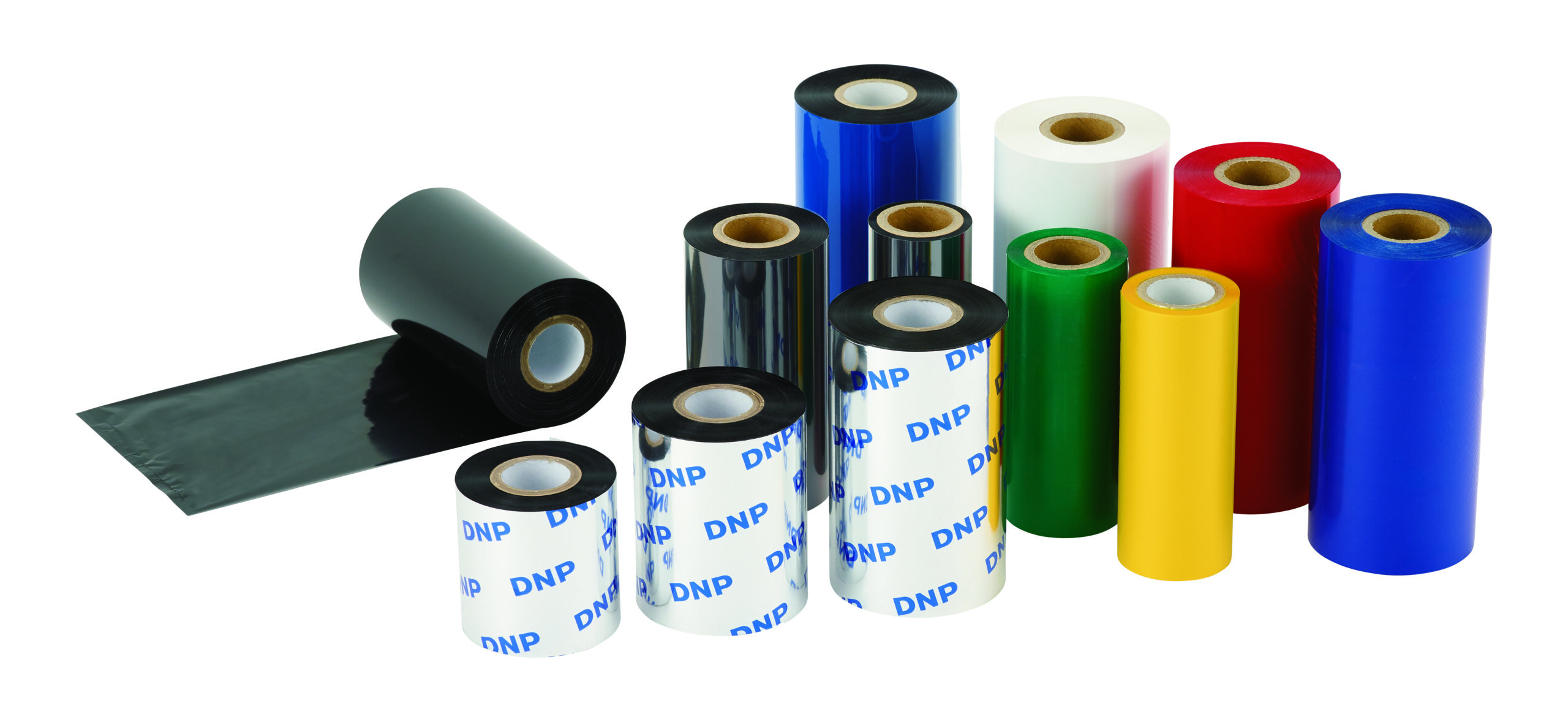

Did you know? Although, you would most commonly use different types of black ribbons for thermal transfer printing, there are also plenty of colour thermal transfer ribbons on the market. These thermal transfer ribbons, just like standard black TTR, come in many different compositions and formulations.

Unlocking the power of colour: Typical applications of thermal transfer ribbon colours

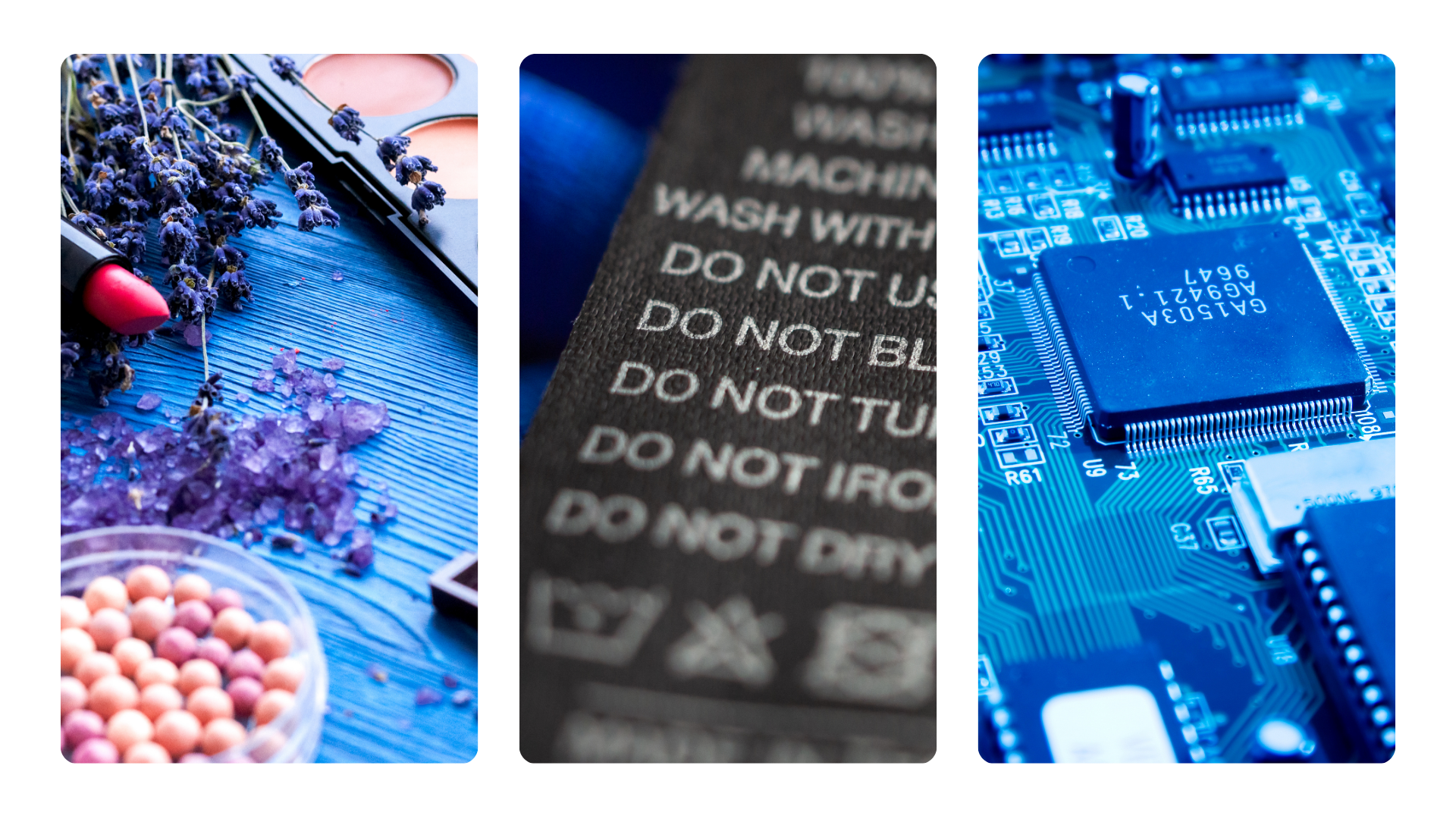

There are endless possibilities of thermal transfer ribbon colour uses. From chemical packaging to electronics manufacturing, these vibrant ribbons find their place in a wide range of applications. Whether it’s enhancing safety labels or adding a touch of elegance to cosmetic packaging, ribbons deliver durability and visual impact. Explore the following list of typical applications:

- Packing of chemicals: In the world of chemical packaging, thermal transfer ribbon play a crucial role. From detergents to disinfectants, these ribbons are essential for creating clear and informative labels. By using colour thermal transfer ribbons, manufacturers can easily differentiate between different types of chemicals, ensuring proper handling and safety precautions. Whether it’s a warning label or a product description, variable data printing make chemical packaging stand out with clarity and professionalism.

- Pharmaceutical items: The pharmaceutical sector often uses Thermal Transfer Printing for labeling purposes. Common uses include test tube labeling, ensuring accurate identification and organisation in laboratory settings. Additionally, this technique is often used for medication packaging, enhancing visual recognition and differentiation.

- Cosmetics: The vibrant world of cosmetics relies on eye-catching packaging and labels. Thermal transfer printing allows for the creation of stunning labels that capture attention and reflect the brand’s identity. From lipsticks to skincare products, colour thermal transfer ribbons add a touch of elegance and distinction.

- Electronics: The electronics industry demands precise labeling and identification of components, especially circuit boards and dark-colored parts. Thermal transfer printing with white, silver or black ribbons offers the ability to print detailed information and symbols on these surfaces, ensuring accurate tracking and assembly.

These are just a few examples of the diverse applications. Their versatility and durability make them invaluable in various industries, where clear and long-lasting prints are essential for safety, organisation, and brand representation.

Exploring the spectrum: Types and varieties thermal transfer ribbons

Different types of thermal transfer ribbons cater to the diverse needs of various applications. Most of applications, however, require a high degree of durability. For this, resins are commonly used. These ribbons provide the exceptional durability, ensuring long-lasting prints that can withstand harsh conditions. Additionally, certain colours are also available in the wax and wax-resin ranges, providing versatility for different printing requirements

While colour ribbons are widely available for flat-head printers, options for near-edge printers are more limited. This is primarily due to the durability requirements of the print. Flat-head print-heads have a longer exposure to the thermal transfer ribbon, ensuring a thorough ink transfer and activation of the binding agent on the ribbon. This ensures optimal fixation of the ink to the substrate, resulting in reliable and well-bonded prints.

As a result, flat head printers have the widest selection of colour thermal transfer ribbon formulations.

The availability of thermal transfer ribbon colours

When it comes to the availability of colour thermal transfer ribbons, there are three main groups to choose from, each offering unique options for diverse printing needs:

- PMS: Thermal transfer ribbons offer a wide range of Pantone Matching System (PMS) colours. This allows for precise colour matching, ensuring consistency and accuracy in reproducing specific hues. Whether it’s corporate branding or specific requirements, these ribbon formulations provide reliability for achieving the desired outcome.

- White with different degrees of opacity: TTR also comes in white with varying degrees of opacity. This is particularly useful when printing on dark substrates such as the ones used on electronics. Just like the density levels of black thermal transfer ribbons, white ribbons have similarly varying formulations with different opacity levels to help achieve the desired level of coverage or contrast required.

- Metallic such as silver and gold with different gloss levels: For a touch of elegance and sophistication, metallic thermal transfer ribbons are available in silver and gold, with different gloss levels. These ribbons add a luxurious and eye-catching element to labels, packaging, or any print that requires a metallic finish. They are particularly popular in industries such as cosmetics, gourmet food, and high-end products, where aesthetics play a significant role.

When it comes to thermal transfer ribbon colours, most ribbon suppliers have a standard selection available in their assortment. Some suppliers may even provide the option to produce custom-made formulations for larger volume orders.

Ensuring safety compliance: Printing hazard symbols with a thermal transfer printer

A typical use of thermal transfer ribbon is in the printing of hazard symbols and warning signs on things like chemical containers. Hazard symbols must remain readable under the most extreme circumstances, which is why ultra durable resins are essential for this task. These ribbons should be matched with a substrate of the same durability. Synthetic label materials, such as Polypropylene (PP) provide the highest degree of durability, ensuring that hazard symbols remain intact and legible.

Hazard symbols should be clearly distinguishable on the packaging. One way to achieve distinctiveness is a two tone print. By combining two thermal transfer ribbon colours, most commonly red and black, you can print hazard symbol with added impact. For this, you can use a multi colour thermal transfer printer, where the information can be printed in a single pass. Alternatively, a standard TTR printer can be utilised by passing the substrate through the printer twice.

To achieve the right durability of such symbols, it is important that both thermal transfer ribbons are from the same, ultra durable type. This is best secured by using ribbons from the same manufacturer and series.

By these guidelines, hazard symbols can be printed with clarity and durability, providing vital information and enhancing safety in various industries.

Enhancing readability on dark backgrounds: Thermal transfer ribbons for optimal printing

When it comes to printing on dark backgrounds, ensuring the readability of the information provides specific challenges. Silver, silver-metallic and white are the logical choices for these applications.

In general, the durability and the opacity of the print result might differ from formulation to formulation. Durability matters in relation to what the print will be exposed to, such as heat, chemicals, abrasion and sunlight. Opacity, on the other hand, determines how “white” a print will appear on the label and to what extend the background is shining through the print. To achieve optimal whiteness, manufacturers provide ribbons with high levels of opacity, sometimes even by applying a double layer of white ink via a single thermal transfer ribbon.

For flexible packaging materials, there are silver and white colour thermal transfer ribbons available specifically designed for near-edge printers. These ribbons meet the ink-release and print-speed requirements of these printers. These color ribbons are commonly used in the printing of packaging materials for cosmetics and packaging of food and beverages.

Harnessing the potential of multi colour thermal transfer printer

Most thermal transfer printers typically contain a single ribbon. However, some manufacturers have introduced multi colour thermal transfer printers to their line-up. These printers can equip two ribbons, allowing for the printing of a substrate with multiple colours in a single pass.

It’s worth noting that these printers generally work with one temperature setting. That is exactly why, ribbons from the same type and preferably the same manufacturer is so important. This helps achieve proper ink transfer and equal print quality and durability.

Perfect harmony: Matching your label and thermal transfer ribbon

The process of matching the thermal transfer ribbon colour and the substrate is no different from a standard black-and-white print. Read more about the necessary steps for an optimal print result in this article.

Colour thermal transfer printers and ribbons in a nutshell

Colour thermal transfer printing has revolutionised the way we print labels and graphics. Whether it’s adding vibrancy to labels, printing hazard symbols, or printing on dark backgrounds, TTR offer versatility. By understanding the applications, types of ribbons, and the importance of matching these with the right label, you can maximise the impact of printed materials.