What is Thermal Transfer Printing?

Thermal Transfer Printing is a method where heat is used to transfer ink from a ribbon onto a substrate. For example, for the printing of barcodes and other variable information.

Why is my Thermal Transfer Print/barcode too faint or too thick?

When printed information looks too light or too heavy, this might be due to the settings of the printer.

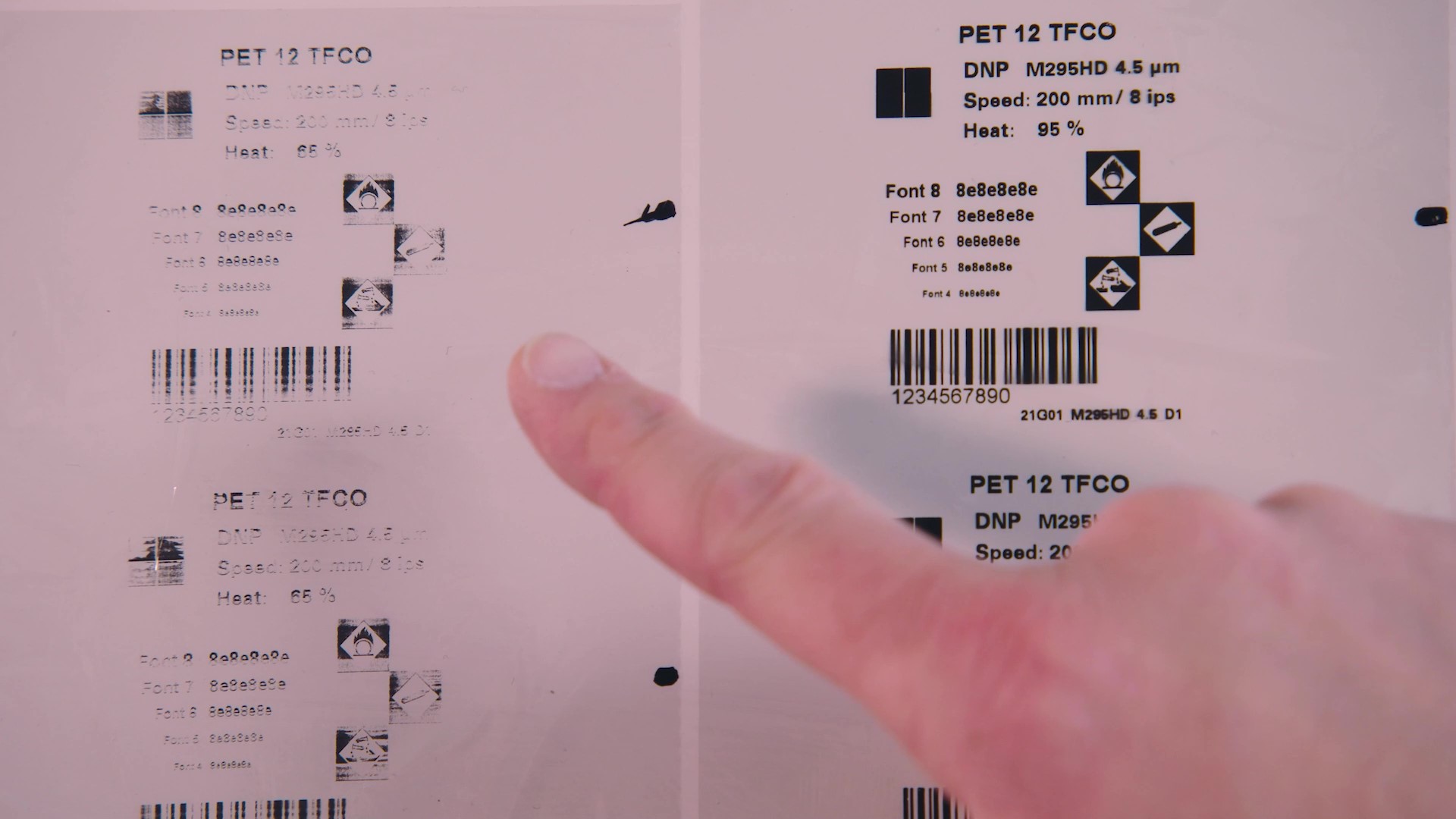

Below on the left-hand side, is an example of either too low temperature or too high-speed settings. As you can see, the print looks faded and incomplete.

On the right-hand side, there is an example of the same ribbon and substrate combination. But in this case, the temperature is either too high or the speed setting of the printer is too low. This results in the print looking too thick and heavy.

How to ensure that my barcode/variable data is not too thick or too faint?

By optimising the printer settings, you can easily troubleshoot this commonly encountered issue. Simply adjust your temperature and speed settings until you receive your desired print results.

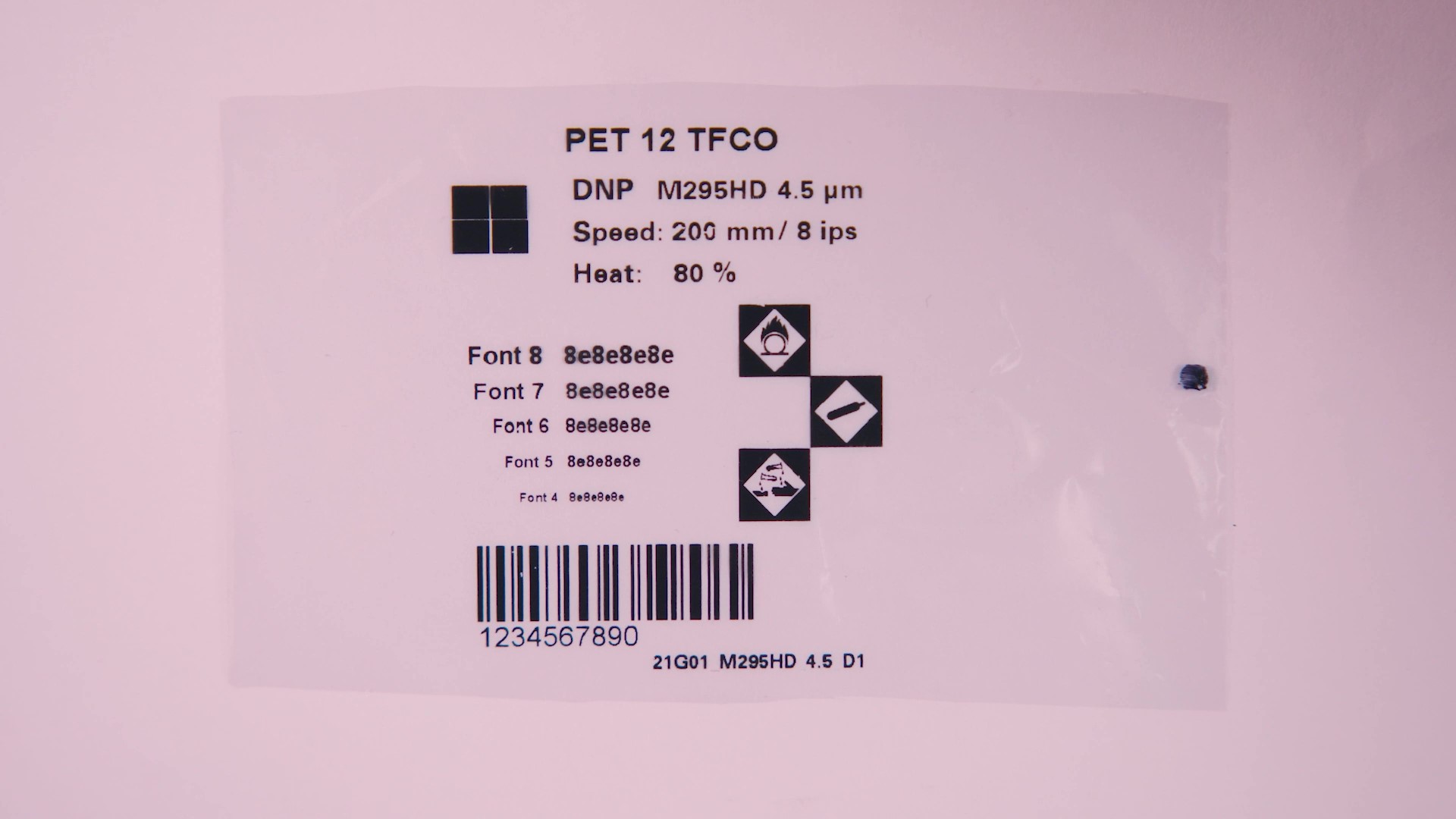

Below you can see an optimized sample print, where we tweaked the temperature and speed settings to receive an optimal print with high-density, scannable barcodes, and other variable data.

Resolve your thermal transfer printing problems

You can easily do this procedure in your given software. But now the question is, which tweaking results in what? Here are a few main points to get you started:

- Decreasing temperature: The print head melts/softens the ink material to a lesser degree, resulting in less ink transfer and/or sharper edges that are not flowing together. Tip: Try this when your initial print result is looking too thick/heavy.

- Increasing temperature: The print head melts/softens the ink material more due to added heat, resulting in an easier transfer of the ink onto the substrate. Tip: Try this when your initial print result is looking too faint/thin/incomplete.

- Decreasing speed: The print head comes in contact with the substrate for a longer time, resulting in an easier transfer of the ink onto the substrate. Tip: Try this when your initial print result is looking too faint/thin/incomplete.

- Increasing speed: The print head comes in contact with the substrate for a shorter time, resulting in less ink transferring unnecessarily. Tip: Try this when your initial print result is looking too thick/heavy.

Often a combination of adjustments on both the temperature and speed settings will result in the most optimal prints.

Do you need some assistance?

We are here to help wit you thermal transfer printing problems! DNP specialises in helping you harmonise substrate, printer, and ribbon. All this, with ribbons tailored to your needs and technical support in our DNP lab or on-site, in your own production environment by our very own Thermal Transfer Experts. So are you in need of some technical support? Don’t hesitate to reach out!