What is Thermal Transfer Overprint?

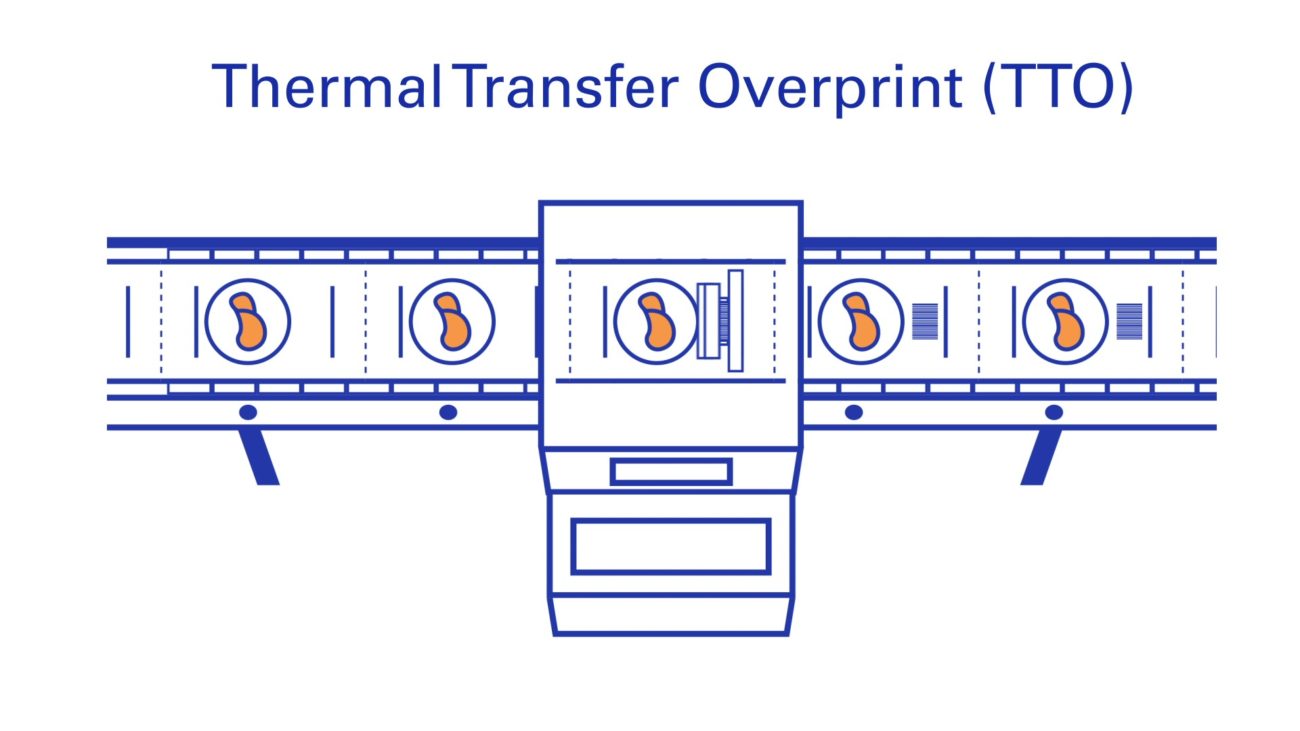

Thermal Transfer Overprint (TTO) is a method where heat is used to transfer ink from a Thermal Transfer Ribbon onto a flexible substrate like food, beverage, and medication packaging. This technique is used for example for the printing of barcodes and variable information such as best-by dates and serial numbers.

What makes TTO challenging?

The challenge of printing on flexible packaging on a high-speed production line is to guarantee high-quality printing with compliant variable data on each and every item. TTO is designed to do just that.

TTO printers are in direct contact with the substrate. This ensures the swift transfer of high-quality variable data onto flexible packaging material such as PP, PET, aluminium, paper and Tyvek.

What requirements are there for Thermal Transfer Overprint Ribbons?

In-line printing is done at high speeds of 20 IPS and therefore needs specific Thermal Transfer Ribbons that release the ink at high speeds and enable long production runs without unnecessary changeovers.

DNP offers a range of TTO ribbons such as and will be introducing several new ribbons in the year to come. The assortment contains products for general applications and specific requirements.

Our technical experts are available to help you install the ribbons according to your specific requirements. More information on these ribbons is available on our product pages. Here you can also request your free Thermal Transfer Ribbon sample. On this page we provide more specific info on the interaction between ribbons and Thermal Transfer Printers.

What ribbons for TTO print does DNP offer?

DNP has developed several ribbons that are specifically designed for TTO print. The product that is most used is M295HD 4.0, this wax/resin is designed for high speeds and works in the majority of applications. This product is also available on a 4.5 micron film. For high speed applications that need a more resistant print, we offer 2 resins. V390 is designed for the most resistant print on a wide range of materials while R396 is more focused on the highest possible print speed. M295HD 4.0, V390 and R396 are all delivered on a 4.0 micron film, allowing longer rolls of up to 2000 meters, enabling longer runtimes and reducing the amount of plastic waste.