Thermal Transfer Printing is a method where heat is used to transfer ink from a ribbon onto a substrate. For example, for the printing of barcodes and other variable data like lot numbers, serial numbers, etc. A good Thermal Transfer print is made to last.

For a good thermal transfer print, the right amount of heat needs to be applied to the ribbon. When the heat settings are incorrect, the print might not be good. For instance, when the temperature is too high, the ribbon might break. That’s what we call ribbon breakage.

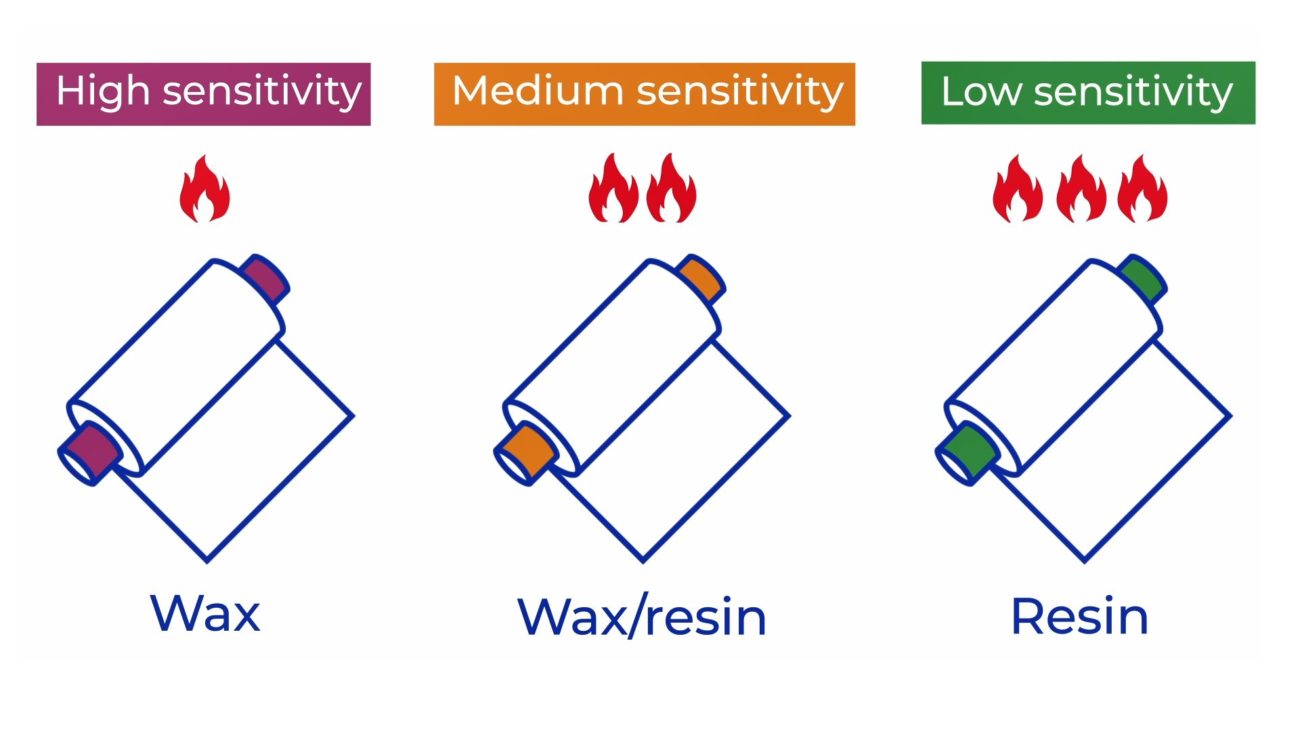

Different types of ribbons require different amounts of heat. This is what we call the print sensitivity of a ribbon.

A ribbon with a high print sensitivity requires less heat to transfer its ink compared to a ribbon with lower print sensitivity. Ribbons with a high print sensitivity or less heat requirement are used for prints in everyday use, where no long-term durability is required. These are often wax ribbons.

Wax/resin and resin ribbons are often used when more durability is required. Ribbons with low sensitivity or high heat requirements are necessary for the most durable prints. These are often resin ribbons.

So, with the right ribbon and heat settings, you secure a high-quality Thermal Transfer Print, and codes that always read and scan and do not use more energy than necessary!

Interested in knowing more about the sensitivity of our ribbons? You can find more information on the product pages of our website. Other specific questions on TTR ribbons are answered on this page.

Would you like to request more information about print sensitivity and or are interested in trying our ribbons? We are here to help!