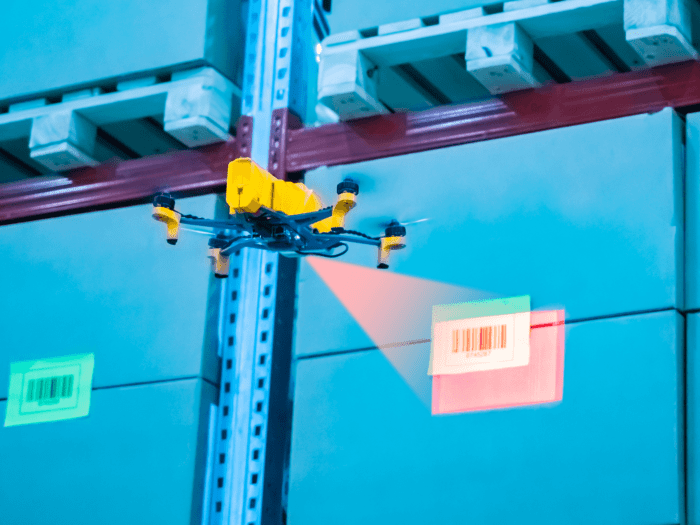

Curious about the possibilities of Wax Thermal Transfer Ribbons for your company? Fast identification of items is a prerequisite for successful business operations. Scanning in logistical processes and in-shop rely on variable codes such as barcodes or lot number that are easy-to-read at any time. The variable information needs to be printed in high quality and needs to withstand the expected treatment of handling it in the supply chain. Our products are designed to ensure the best possible variable print.

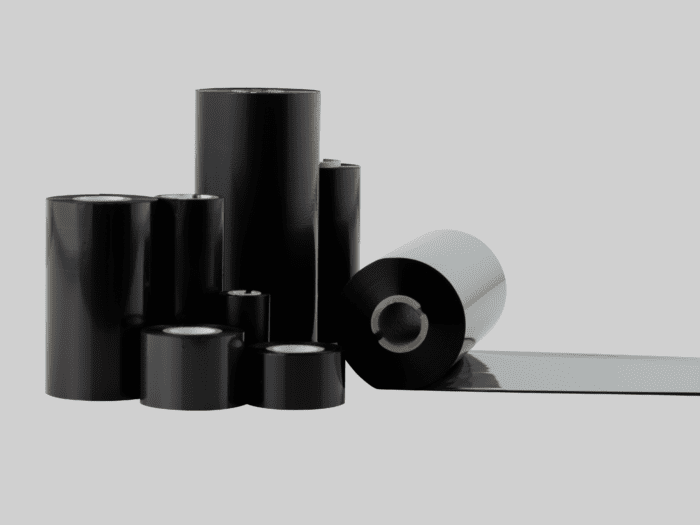

Certainly, Wax Ribbons continuously appear as a flexible and durable technique, delivering crisp prints that withstand the test of time. In general, these ribbons are the standard for printing on (un)coated paper and other materials with a rougher surface. All this, due to the product characteristics helping fill up uneven surfaces, delivering high optical density print for scannable barcodes and other variable codes.

Find the right Wax Thermal Transfer Ribbon for your application requirements.

In such a ribbon, the pigments of the ink are captured in wax. The wax is quite soft and therefore transfers at relatively low temperatures. It also fills up unevenness in the surface of the printed material/substrate. Therefore, wax ribbons are the standard for printing on (un)coated paper and other materials with a rougher surface. Due to the ability to fill up uneven surfaces, these ribbons deliver a high optical density print for scannable barcodes and other variable information.

When it comes to wax ribbons, significant differences are usually present when compared to wax resin and resin ribbons:

All DNP ribbons are formulated to consistently deliver high-quality variable print. From standard coding to highly specific applications and substrates, we supply a ribbon that fits your needs.

Wax products can fulfill the bulk of Thermal Transfer Printing jobs, where moderate durability is required. Since these ribbons require the lowest printing energy (lower melting temperature), the ink easily transfers onto the substrate. For instance, for logistical operations and most identification tags, waxes can deliver the necessary durability to secure vital scanning operations. However, when an application requires higher durability and resilience against chemicals and environmental factors, we mostly recommend wax/resin or resin ribbons.

Wax ribbons are used for easy printing of variable information in scanning operations with a fast turn-around time. They print especially well on rough materials such as uncoated paper.

Since the early ’80s, DNP (Dai Nippon Printing Co. Ltd.) has built-up a long-standing history of developing Thermal Transfer Ribbons. DNP’s TR4085plus® is widely recognised as the quality reference in wax. Also, DNP offers a comprehensive range of ribbons for black, colour and even transparent printing. Some DNP wax qualities are resin enhanced, making them suitable for different label stocks and more demanding applications with increased abrasion and smudge resistance. Additionally, DNP developed all ribbons with an exclusive back-coating technology that delivers anti-static properties for easy handling, uninterrupted print and superior printhead protection.

As an experienced wax ribbon manufacturer, DNP has extensive knowledge on delivering quality ribbons. Our meticulous quality controls ensure a product that delivers the same performance time after time. We take great pride in making our product work for you!

DNP specialises in helping you harmonise substrate, printer and ribbon. All this, with ribbons tailored to your needs and technical support in our DNP lab or on-site, in your own production environment.

Because at DNP, we believe in partnership, that provides the swift and tailor-made answers that you need.